Life cycle thinking in sustainable waste management

In addition to waste hierarchy we covered in one of our previous articles, the EU Waste Framework Directive has introduced the Life Cycle Thinking into waste policies, a concept proving to be increasingly important in good waste management.

While following the five-step waste hierarchy should generally lead to the most resource-efficient and environmentally friendly way of dealing with waste, the best choice in a particular situation often depends on a number of conditions that are specific to particular waste streams and local circumstances.

In other words, departing from the waste hierarchy is sometimes necessary. As stated in the Article 4 of the Directive, Life Cycle Thinking can be used to complement the waste hierarchy in order to identify the best solution for every particular situation.

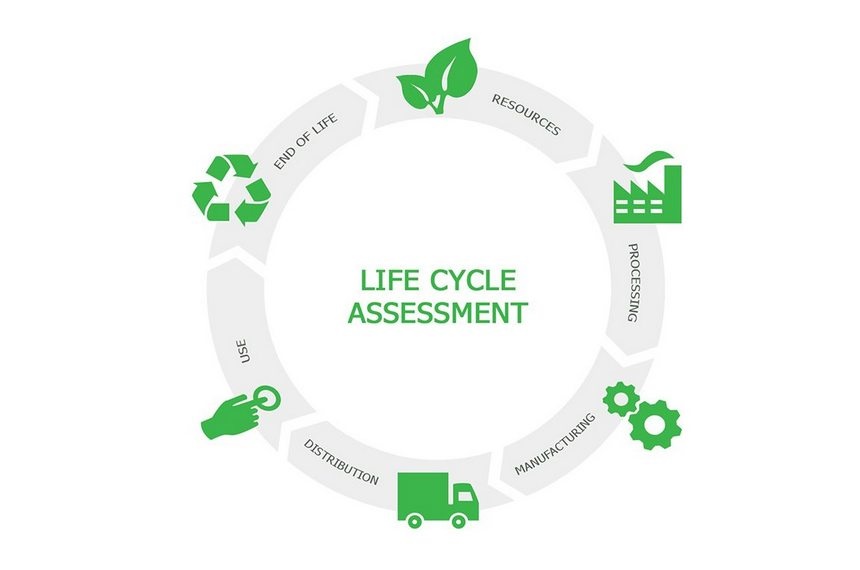

Life Cycle Thinking considers the range of environmental impacts throughout the life-cycle of a product and Life Cycle Assessment tool quantifies those impacts by assessing the emissions, resources consumed and pressures on health and the environment for any product while taking into account its entire life cycle, from the extraction of resources through processing and manufacturing to distribution, consumption and finally, the re-use, recycling, energy recovery and the disposal of remaining waste. This information puts potential environmental advantages and disadvantages into perspective and results in more sustainable decision-making in waste management.

One of the main objectives of life cycle thinking is to avoid the shifting of burden (resolving one environmental problem while creating others) by making sure that reducing the environmental impact at one stage in the life cycle does not increase the impact at other places in the cycle, for example improving production technologies while causing more waste or more unrecyclable waste in the end stage.

For example, when deciding whether it is better to replace appliances with new, more efficient models or keep using the old ones to avoid generating waste, Life Cycle Thinking can be extremely helpful.

A life cycle study has shown that it is sometimes better for the environment to replace an old washing machine, despite the waste generated, than to continue to use an older machine which is less energy-efficient and resource-efficient, because a washing machine’s greatest environmental impact is during its use phase.

In the study, replacing the old machine (category C) with the new (category A) instead of continuing to use it led to lower energy consumption and emission reductions equivalent to around 10 kg of carbon dioxide over a period of five years. However, to determine the best solution for every particular product or a situation, a Life Cycle Assessment needs to be made.

Even more so than in individual consumers’ choices, Life cycle thinking is becoming especially important for policy makers and businesses, because decisions in favour of one option over another can be based on factual, verifiable data. Through implementing life cycle thinking, companies can recognize the environmental impacts of their waste management plans and strategies, how each design and manufacturing decision affects the environment and how to make every phase of the process more sustainable. It can also help policy makers understand the environmental and economic benefits and trade-offs when making decisions on waste management strategies on local and regional levels.

In today’s increasingly complex waste management systems and demanding environmental protection targets, Life Cycle Thinking and Life Cycle Assessment are proving to be powerful tools in optimizing waste management strategies and policies and making them more sustainable.

Sources:

Life Cycle Thinking and Assessment

2008 Life Cycle Assessment study

Author: Ivan Petarčić (RRiF-plus d.o.o.)

Follow us on